Vita Coco Farmers Organic

IS SOURCED FROM SMALL FARMS IN THE PHILIPPINES

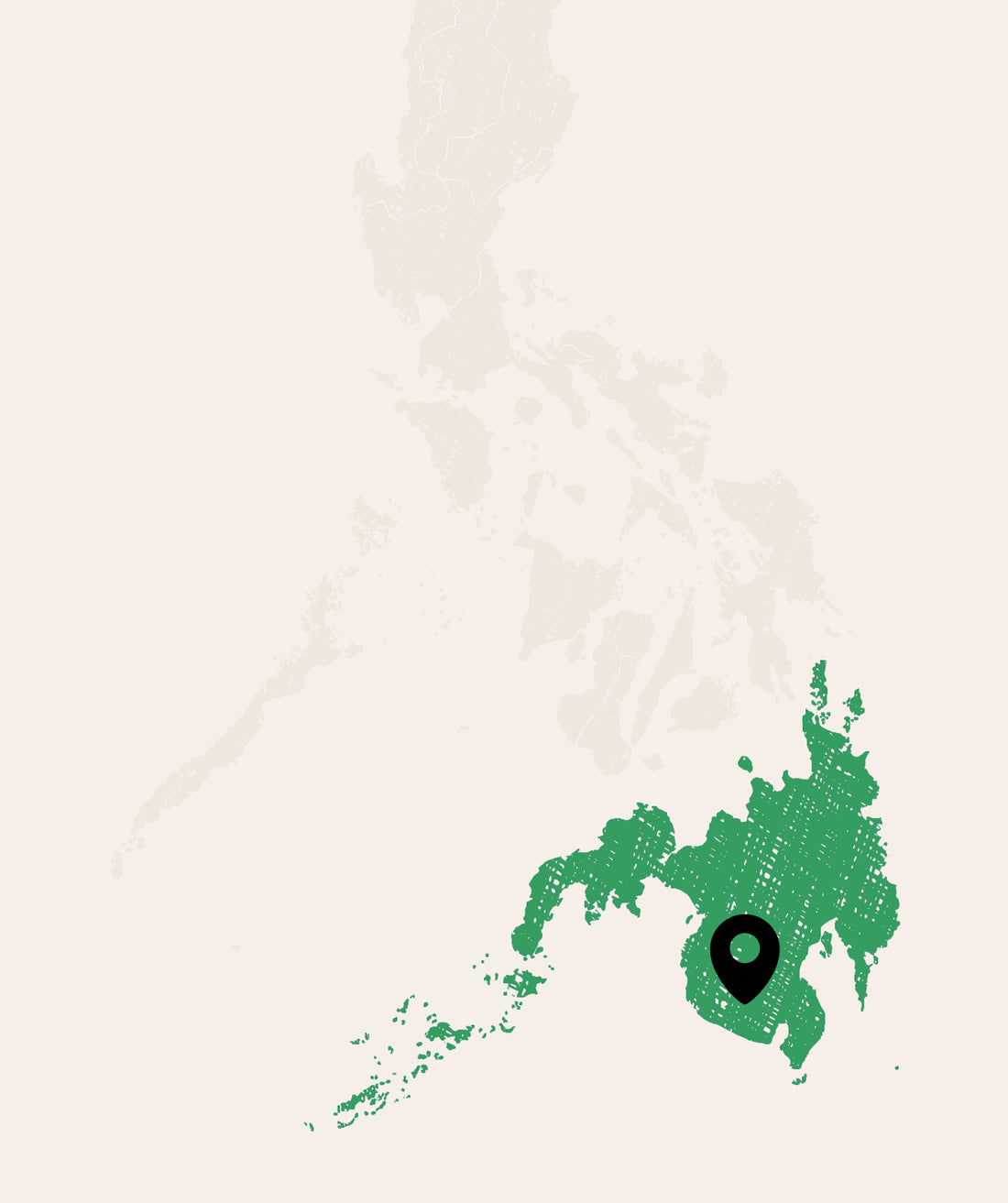

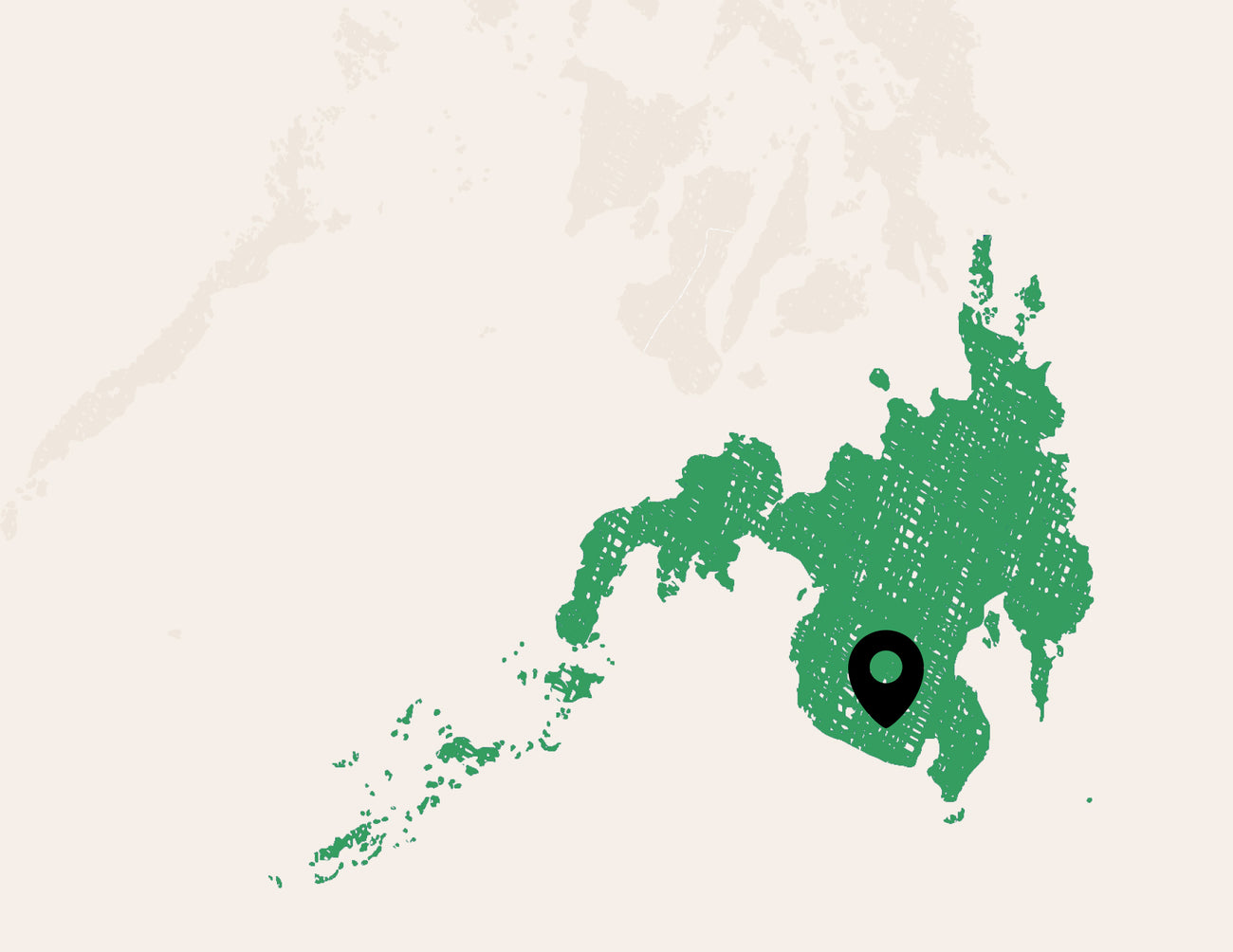

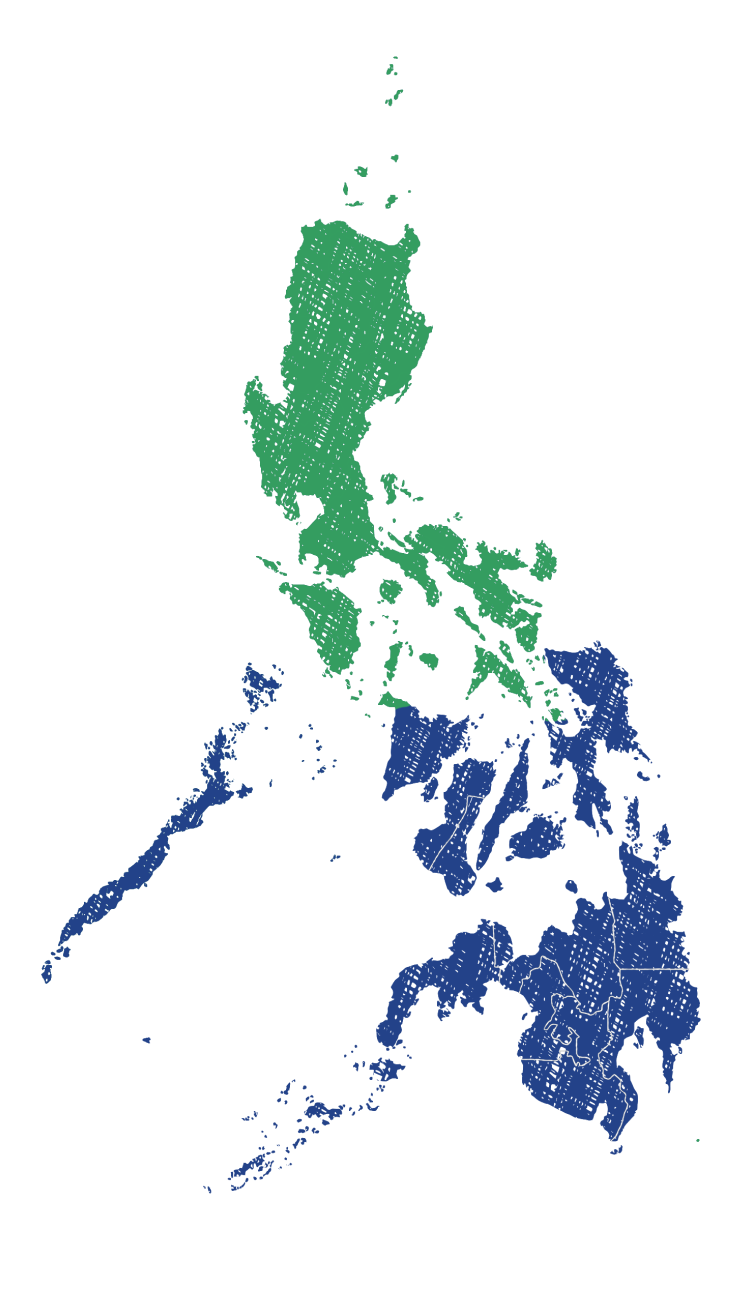

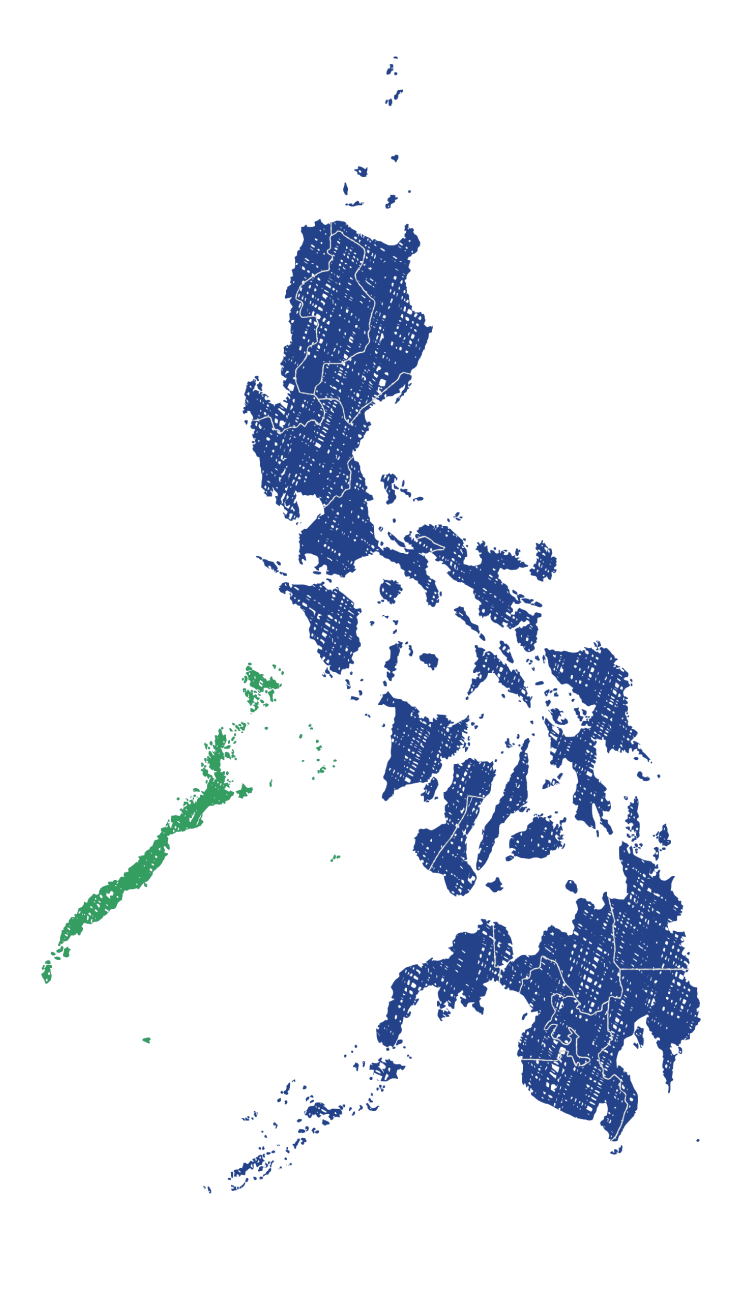

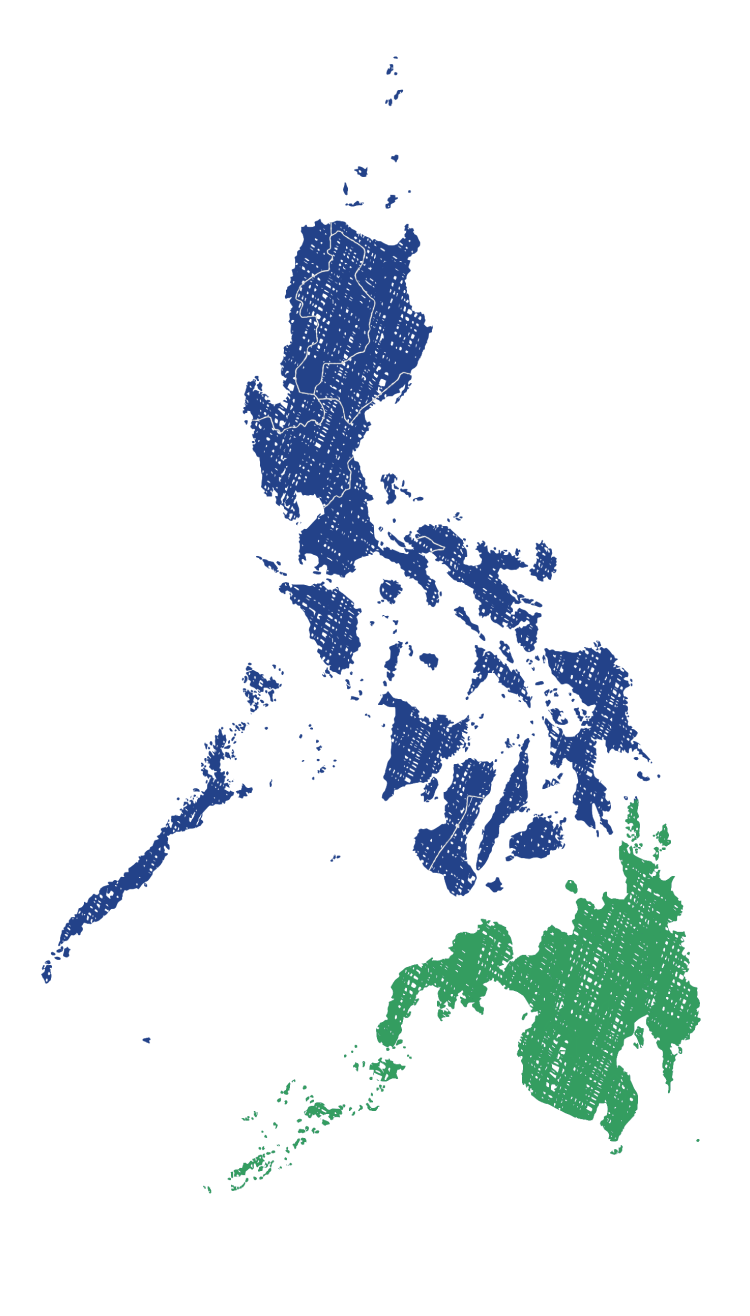

The Philippines

Vita Coco works with tens of thousands of farms across the Philippines to source the best coconuts for the coconut water you know and love. A major industry in the Philippines, coconuts are critical to the health of the local economy. So much so that many consider coconut trees the tree of life, covering an astounding 8.9 million acres of land in the country. That’s equal to 347 million trees! Coconut trees thrive in tropical climates, which makes the Philippines an ideal place to source coconuts from.

Planting the Seedlings

-

The difference between our organic and non-organic products is how the coconuts are farmed. When you're drinking our Farmers Organic Coconut Water, you're drinking coconut water from coconuts harvested on certified organic farms only. The certification process isn't cheap, but through Vita Coco's agriculture initiatives, we're able to support our farmers so that they can enter our trainings and transition to organic certification as easily as possible.

-

Coconuts grow best in somewhat shady areas. Since coconut palms grow in tropical regions, they can be planted at any time of the year.

-

To plant a coconut seedling, farmers cut a mature coconut and bury it partially with dirt. From there, the seedling takes approximately three months to sprout. During the growing process, the seedlings require very little maintenance, other than an occasional watering.

-

Once the seedling sprouts are two to three feet high, they are ready to be replanted fully. When planted with our seedling partners, the seedlings have about a 90 percent germination rate.

-

Many coconut trees in the Philippines are senile, which means they're more than 60 years old and no longer produce the same amount of coconuts (or any coconuts at all). Consistent seedling distribution is critical because farmers need to grow new coconut trees in order to continue producing any coconuts at all.

Coconuts? What makes them Organic?

Beneath the surface

Vita Coco Farmers Organic coconut water comes from USDA certified-organic farms. In order to get those certifications it requires a rigorous review process that examines many things including: soil quality, pest control, and animal raising practices. It also requires the use of non-synthetic additives.

Coconuts, Repurposed

Another popular fertilization method among organic farmers in the Philippines is to use leaves and coconut husks as compost. Not only is using an organic fertilizer better for the environment, it's better for the health and well-being of the farmers and their communities. It turns out that the right way for the planet is the right way for the people, too.

Crops Aplenty

After the coconut crop success that our farmers have had with organic fertilizer, they've expanded their harvest to other fruits and vegetables.

An Organic Journey

Many of our farmers have been using these organic fertilizing methods for years, but getting their farms certified by the Philippine Coconut Authority makes them officially official. And ultimately, that certification is the reason we can call this coconut water "Farmers Organic."

FACTS TO EXPLORE

Coconut trees produce fewer coconuts as they age. The coconut tree reaches its peak coconut production age anywhere from 20 to 30 years after planting. They live between 30 to 80 years, depending on the type of coconut tree.

So, all of this talk about coconuts, but how do we get coconut water? Let's break it down, literally.

There are about 15 different varietals of coconuts, but typically they come from three types of coconut trees:

Preparing the Coconuts

You've learned where the coconut water you've been drinking came from. You've learned how to plant coconut seedlings and how they become coconut trees. You've learned about the lifecycle of coconut trees and the anatomy of a coconut. But what happens after the coconuts are ready to be picked? Well, read on.

Preparing the Coconuts

You've learned where the coconut water you've been drinking came from. You've learned how to plant coconut seedlings and how they become coconut trees. You've learned about the lifecycle of coconut trees and the anatomy of a coconut. But what happens after the coconuts are ready to be picked? Well, read on.

Picking the Coconuts

Coconuts, sound off! Or should we say... on? Farmers know the coconuts are ready to be picked when they have a clear sound when they're hit. The sound identification is important to distinguish which coconuts are ready to come off the tree since coconut trees need nine to 11 months to produce mature coconuts, which all grow at different times.

Picking the Coconuts

Coconuts, sound off! Or should we say... on? Farmers know the coconuts are ready to be picked when they have a clear sound when they're hit. The sound identification is important to distinguish which coconuts are ready to come off the tree since coconut trees need nine to 11 months to produce mature coconuts, which all grow at different times.

Dehusking the Coconuts

The green, outer coconut shell, is the mesocarp. It's the husk of the coconut and once we pull it off (a process known as "dehusking") we use it as organic fertilizer, feed for animals, and so much more. Think of this step like shucking corn.

Dehusking the Coconuts

The green, outer coconut shell, is the mesocarp. It's the husk of the coconut and once we pull it off (a process known as "dehusking") we use it as organic fertilizer, feed for animals, and so much more. Think of this step like shucking corn.

Loading the Coconuts

Off they go! The coconuts, still with their brown shells on, are loaded onto trucks to be brought to the factory. It's almost time for the coconut water magic to happen...

Loading the Coconuts

Off they go! The coconuts, still with their brown shells on, are loaded onto trucks to be brought to the factory. It's almost time for the coconut water magic to happen...

Transporting and Producing

The coconuts are now dehusked and on trucks on their way to the factory. But we still have exactly that: coconuts. How do we actually get the coconut water out? It's definitely not just a one-step process, that's for sure.

Transporting and Producing

The coconuts are now dehusked and on trucks on their way to the factory. But we still have exactly that: coconuts. How do we actually get the coconut water out? It's definitely not just a one-step process, that's for sure.

Testing the Coconuts

Once the coconuts arrive on trucks to the factory, they're tested by sound again - just like when figuring out if they're ready to be picked off the trees. Only the finest coconuts go into the factory. The ones that don't pass the sound test get sent back to supplier farms, where they are often dried out and turned into copra, which is dried coconut shavings.

Testing the Coconuts

Once the coconuts arrive on trucks to the factory, they're tested by sound again - just like when figuring out if they're ready to be picked off the trees. Only the finest coconuts go into the factory. The ones that don't pass the sound test get sent back to supplier farms, where they are often dried out and turned into copra, which is dried coconut shavings.

The Coconut Conveyor Belt

The workers in coconut factories rely on a range of methods to test the quality of the coconuts. One way they can actually check how much water is in each coconut is by texture. Any coconut that doesn't pass the texture test is used for other products - nothing goes to waste! The conveyor belt workers drill holes into the three coconut pores (also called pits, which are kind of like the finger holes in a bowling ball). The coconuts are then drained and filtered. Fun fact: 40 - 50 thousand coconuts are processed per hour (that's over four thousand gallons of coconut water!).

The Coconut Conveyor Belt

The workers in coconut factories rely on a range of methods to test the quality of the coconuts. One way they can actually check how much water is in each coconut is by texture. Any coconut that doesn't pass the texture test is used for other products - nothing goes to waste! The conveyor belt workers drill holes into the three coconut pores (also called pits, which are kind of like the finger holes in a bowling ball). The coconuts are then drained and filtered. Fun fact: 40 - 50 thousand coconuts are processed per hour (that's over four thousand gallons of coconut water!).

Skin Removal & Coconut Meat Processing

Once all the coconut water has been drained, our coconut specialists remove the brown skin (called the testa) and use it for animal feed. The coconut meat is used for food and coconut oil. After being drained, the coconut water goes into a 500ml processing filtration tank, where any unsterile bits are separated from the water. Once the tank is full, they test it for acidity, clarity, pH levels, and sweetness level. This way, if the batch is not desirable, they only have to discard 500ml versus the entire production run to minimize potential waste.

Skin Removal & Coconut Meat Processing

Once all the coconut water has been drained, our coconut specialists remove the brown skin (called the testa) and use it for animal feed. The coconut meat is used for food and coconut oil. After being drained, the coconut water goes into a 500ml processing filtration tank, where any unsterile bits are separated from the water. Once the tank is full, they test it for acidity, clarity, pH levels, and sweetness level. This way, if the batch is not desirable, they only have to discard 500ml versus the entire production run to minimize potential waste.

Pasteurization & Bottling

Once the coconut water meets our high quality standards for acidity, clarity, and sweetness, we’ll pasteurize it to make sure that the coconut water is safe to drink. The pasturization process is how we sterilize the coconut water so the highest-quality coconut water makes its way to your local stores. During this process, we add one gram of sugar to standardize taste and make sure every sip is the same, sweet experience. Then, it’s off to filling, sealing, and capping our Tetra Paks®.

Pasteurization & Bottling

Once the coconut water meets our high quality standards for acidity, clarity, and sweetness, we’ll pasteurize it to make sure that the coconut water is safe to drink. The pasturization process is how we sterilize the coconut water so the highest-quality coconut water makes its way to your local stores. During this process, we add one gram of sugar to standardize taste and make sure every sip is the same, sweet experience. Then, it’s off to filling, sealing, and capping our Tetra Paks®.

Packing the Coconut Water

The coconut water in Tetra Paks® are then boxed by hand and loaded onto pallets for shipping. To make sure the boxes don’t shift in transit, they’re wrapped in secure packing film. Once loaded on the pallet, they’ll sit in the warehouse for at least 72 hours, going through one last quality assurance check. Then, it’s off to the warehouse and one step closer to you!

Packing the Coconut Water

The coconut water in Tetra Paks® are then boxed by hand and loaded onto pallets for shipping. To make sure the boxes don’t shift in transit, they’re wrapped in secure packing film. Once loaded on the pallet, they’ll sit in the warehouse for at least 72 hours, going through one last quality assurance check. Then, it’s off to the warehouse and one step closer to you!

INTRODUCING OUR TETRA PAK®

Our Farmers Organic Tetra Paks® offer the same healthy, cost-effective, and easy-to-prepare products, without bisphenol A (BPA) or Bisphenol S (BPS). BPA and BPS are organic compounds that are sometimes found in hard plastics.

Because of the sterilization process we use, our products have a shelf life of at least six months without refrigeration.

The majority of the bottles are made from plant-based materials that can then be recycled into new paper-based products.

Operations at Tetra Pak® are optimized for minimum climate impact because they are powered by renewable energy, use manufacturing processes that are highly efficient, and employ logistics that reduce fuel use.

Shipping across the globe

Shipping across the globe

Once the Tetra Paks® have been filled and tested, it's off to the port to be transported by shipping container. We use ocean freight carriers, which emit one of the lowest carbon footprints of any form of mass transportation.

CAGAYAN DE ORO, PHILIPPINES

Most of Farmers Organic will be loaded on shipping containers in the port city of Cagayan de Oro, Philippines. Then, it takes five to seven days to arrive at a trans-shipment port to be consolidated with other products.

KAOHSIUNG, TAIWAN

One of the many routes our containers take includes a stop in Taiwan. The port city of Kaohsiung houses many trans-shipment containers. These shipping vessels help optimize bulk transportation of goods to efficiently move large volumes of product across the world, while keeping our carbon footprint in mind. From here, it's off to the United States by way of the Pacific Ocean!

LOS ANGELES, CALIFORNIA

Once Farmers Organic has reached the United States, it's off to the races - arriving at a store near you! We work with a network of highly skilled logistics carriers to help distribute our coconut water to stores, wholesalers, and fulfillment centers across the country.

Ready for you to enjoy!

You should be sipping on that hydrating, refreshing, and nutrient-packed coconut water you know and love within the week! And that's that.

Ready for you to enjoy!

You should be sipping on that hydrating, refreshing, and nutrient-packed coconut water you know and love within the week! And that's that.